ORGANIZATION

PERFORMANCE GROUP

PRODUCTION

QUALITY ASSURANCE & PRODUCT SAFETY

INDUSTRIAL ENGINEERING

DEVELOPMENT

WAREHOUSE

MANAGING PARTNER

MANAGEMENT GROUP

GENERAL AFFAIRS

ACCOUNTING

HUMAN RESOURCES

COMPLIANCE

IMPORT/ EXPORT

CAPACITY DETAIL

FACTORY |

BUILDING # |

# OF LINE |

KEY ITEM |

#OF EMPLOYEE |

MONTHLY CAPACITY |

| TWI | 1 | 08 | T-SHIRT | 96 | 5,20,000 |

| 2 | 06 | BOXER BRIEF | 72 | 3,90,000 | |

| 3 | 06 | A – SHIRT | 72 | 3,90,000 | |

| 4 | 04 | KNIT PANT | 60 | 1,30,000 |

Factory |

Machine List |

Key Item |

# of Employee |

Daily Capacity |

Remarks |

| Washing |

1 sample washing machine 1 sample dryer 1 sample hydro extractor |

Wet Wash: Normal, Enzyme, Stone | 30 | 25,000 pcs without shift | Currently running |

KNITTING

Our knitting products are designed to meet the needs of knitters and textile enthusiasts of all levels.

DYEING

Our dyeing process is designed to produce fabrics and yarns that are both beautiful and functional.

COMPACTING

We are committed to deliver high standard quality products by conducting 100% inspection of fabrics inhoused for production.

PRINITING

Our printing process is designed to produce high-quality, eco-friendly fabrics and garments that are both beautiful and functional.

EMBROIDERY

Computerised multi head embroidery machines to make chain, loop stitch and chenneli designs up to 8-9 colors on Japanese make Barudan machine.

CUTTING

Our cutting process is designed to produce high-quality fabrics and garments that are both functional and beautiful.

STITCHING

Legal and statutory norms with respect to social systems and physical facilities are provided.

CHECKING

Checking is to trim all extra threads and also checks for stains and holes. All garments are 100% checked before packing.

WASHING

Our washing process is designed to produce high-quality, clean, and comfortable fabrics and garments that are both functional and beautiful.

IRONING

Automated ironing lines work in tandem to ensure smooth ironing of all the products.

PACKING

We buy our packing materials from leading suppliers and professional providers.

LAB

Our laboratory conducts a wide range of tests on raw materials, intermediate products, and finished textiles to ensure they meet our strict quality standards.

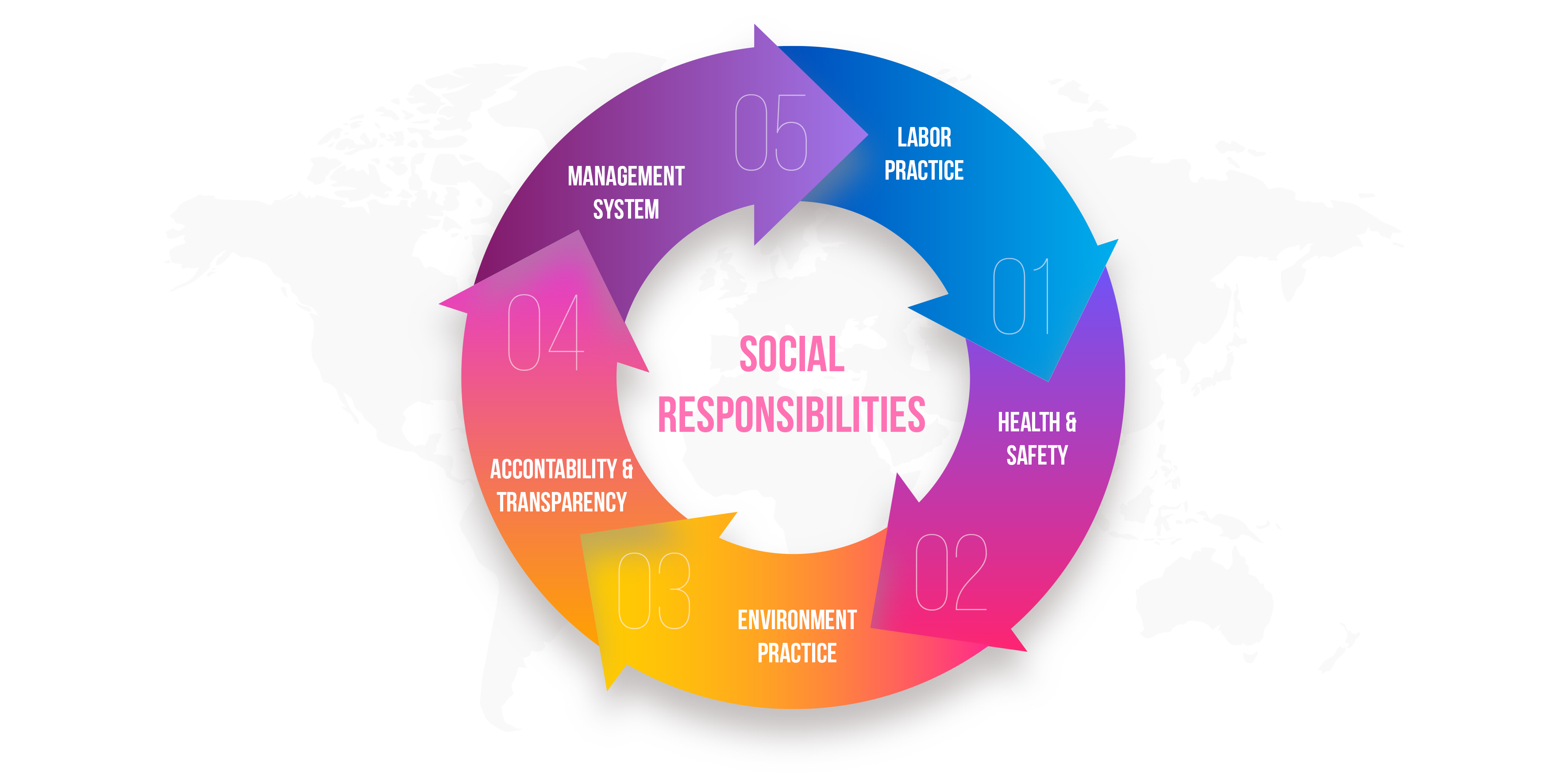

APPROVED BY AUTHORITIES

FACTORY EVALUATION

2 MONTH PROCESS

REQUEST FACTORY EVALUATION

FACTORY AUDIT

SUBMIT CAP & FOLLOW-UP ON REMEDY, IF ANY

FOLLOW-UP AUDIT, IF ANY & FACTORY REGISTRATION

STARTING PRODUCTION UPON APPROVAL

Brands approved: Hanes, Wal-Mart & Kohl’s

FCCA (FACTORY CAPABILITY & CAPACITY AUDIT) by Intertek with a score of 94.2/100

WRAP (Worldwide Responsible Accredited Production) approved by TUV Nord

SMETA (Sedex Members Ethical Trade Audit) approved by Intertek

C-TPAT: Approved by Global Security Verification (GSV) by Intertek with a score of 85/100

SCS (Supply Chain Security) by Intertek with a score of 94/100

Currently, factory evaluation processes are being taken/ planned for Levi’s, and others.

INSPECTION & TESTING

Description |

# of Sample / Standard |

Remark |

|

| Material Quality Inspection | Fabric appearance test | 10% / 4 Point System | Following higher standard in case of discrepancies between customer’s requirement and factory SOP |

| Material appearance test | AQL 1.5 | ||

| Fabric shrinkage test | +/- 5% | ||

| Fabric weight test | All lots / based on the requirements | ||

| Shade band test | 100% / based on the requirements | ||

| Fabric washing test | 5 times per sample / based on the requirements |

Description |

# of Sample / Standard |

Remark |

|

| Product Safety Testing | Attachment pulling test | 2 times per day / based on the requirement | Once bulk starts, 100% inline check |

| Colorfastness test | Based on the requirement | ||

| Neck stretch test | Initial pp sample testing / based on the requirement | ||

| Sharp tool test | 1 time in the pp stage / based on the requirement | ||

| Washing test | One time in the pp stage and 2 pcs per daily production / based on the requirement |

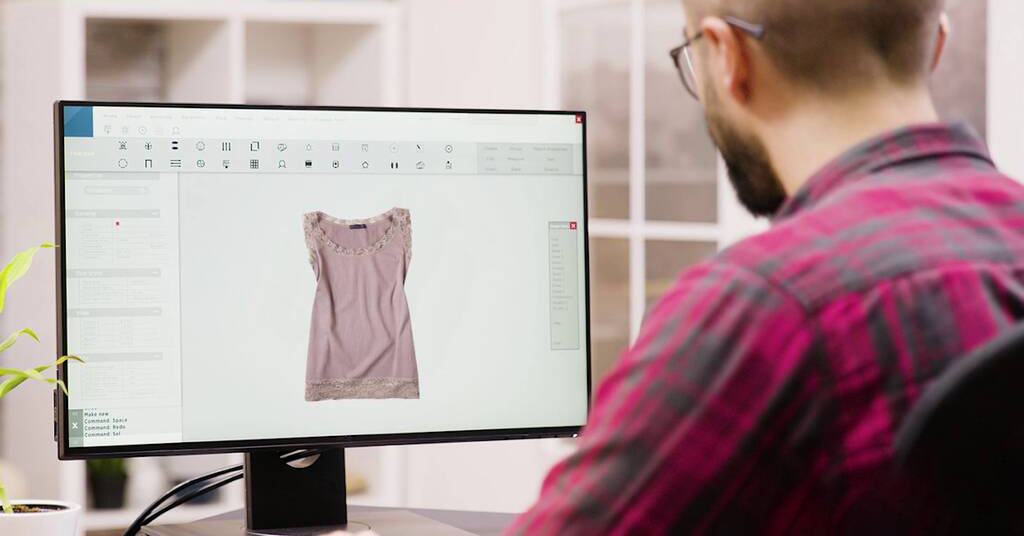

DEVELOPMENT

Current (person) |

Plan (person) |

|

| Pattern making | 1 | 1 |

| Sampling making | 10 | 15 |

| # of employee | 15 | 15 |

| Monthly pattern making capacity | 50 | 50 |

| Monthly sample making capacity | 1000 | 1000 |

| Number of brands | 5 | 5 |

- AD Software: Morgan MD 900 CAD;

- Capable of developing pattern and development sampling

- Module lines available for small lots, test orders

SUSTAINABLE YARNS

Natural, recycled and recyclable

MADE IN TIRUPUR

We ship globally from our INDIA based factory

ETHICAL PRODUCTION

Read our Modern Slavery statement

Let’s Start This Party

Get in touch with us today to see how we can help